How to connect LED strips

Connecting LED strips – connectors and soldering

The LED strips offer many different arrangement options. However, some lighting installations require joining several sections of the strips together. The LED strips can be connected with each other using dedicated accessories or with a soldering iron.

Connecting LED strips in series or in parallel

The LED strips can be connected with each other in two ways: in series and in parallel.

Series connection: a series connection of LED strips consists of the joining of consecutive sections of the strips together. This connection method is recommended for short sections of the strips.

Parallel connection: in this connection, each length of the strip is connected directly to the power supply. This connection method prevents voltage drops.

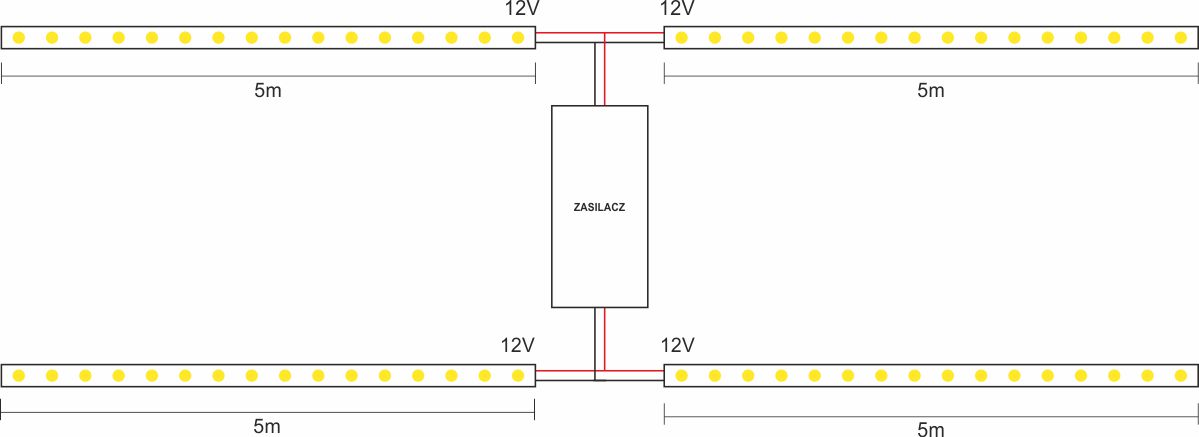

Connecting longer sections of the LED strip

Sections longer than 5 m should not be connected together - such a connection may cause voltage drops. Connecting the LED strips to one power supply should be made in accordance with the diagram:

How to connect the LED strip without soldering

Use dedicated connectors for LED strips to connect sections of the LED strips without soldering. They allow for quick and easy assembly without the need to have a soldering iron. When choosing connectors, pay attention to the width and type of the LED strip. Some connectors are intended for single-colour strips, others for the RGB or RGBW strips.

Connector for the LED strip

The LED strips can be connected by soldering and connectors. The connectors should be properly selected for the type and width of the strip (e.g. RGB).

Connectors variants:

Single-colour LED strips: 8 mm, 10 mm

RGB strips: 10mm

RGBW strips: 10mm, 12mm

Elbow connector: enables connecting strips at an angle

All of the above connectors can be found by clicking the link here.

How to connect LED strips in silicone

The LED strips with a higher IP rating are protected with a silicone coating. To connect these strips, gently remove the silicone layer from the connection point, then use connectors to connect the two sections of the LED strip.

How to solder LED strips?

Soldering is another method to connect the LED strips.

Firstly, you need to prepare the necessary items:

- Transformer soldering iron

- Tin soldering metal

- Strips and cables for soldering

1. Preheat the soldering iron (temperature should be in the range of 320-380°C)

2. Apply the solder in the designated places on the LED strip (all information about these places can be found in the link)

3. Connect the points with the applied solder in a horizontal motion.

4. Wait a few seconds for the solder to cool down.

How to solder LED strips in silicone?

To connect the sections of the waterproof strip by soldering, carefully remove the silicone layer, then solder the LED strips in appropriate places. To protect the soldering point, use a transparent heat shrink coupler. It is worth remembering that the light of the LED diodes will be slightly dimmed in the place of the connector.

0

0